Shift into higher gear to overcome automotive disruptions

Integrated logistics brings greater flexibility and agility to your supply chain.

Be ready to overcome disruptions with resilience, adaptability and strategic transformation

Transformational changes in the automotive industry are driving a greater focus on connectivity and the need for a resilient supply chain to ensure all OEM components arrive on time for production. The right logistics partner can play a significant role in helping forecast trends and create new market opportunities. With digital visibility tools and proactive integrated solutions, Maersk empowers your automotive supply chain for long-term success, helping you go all the way.

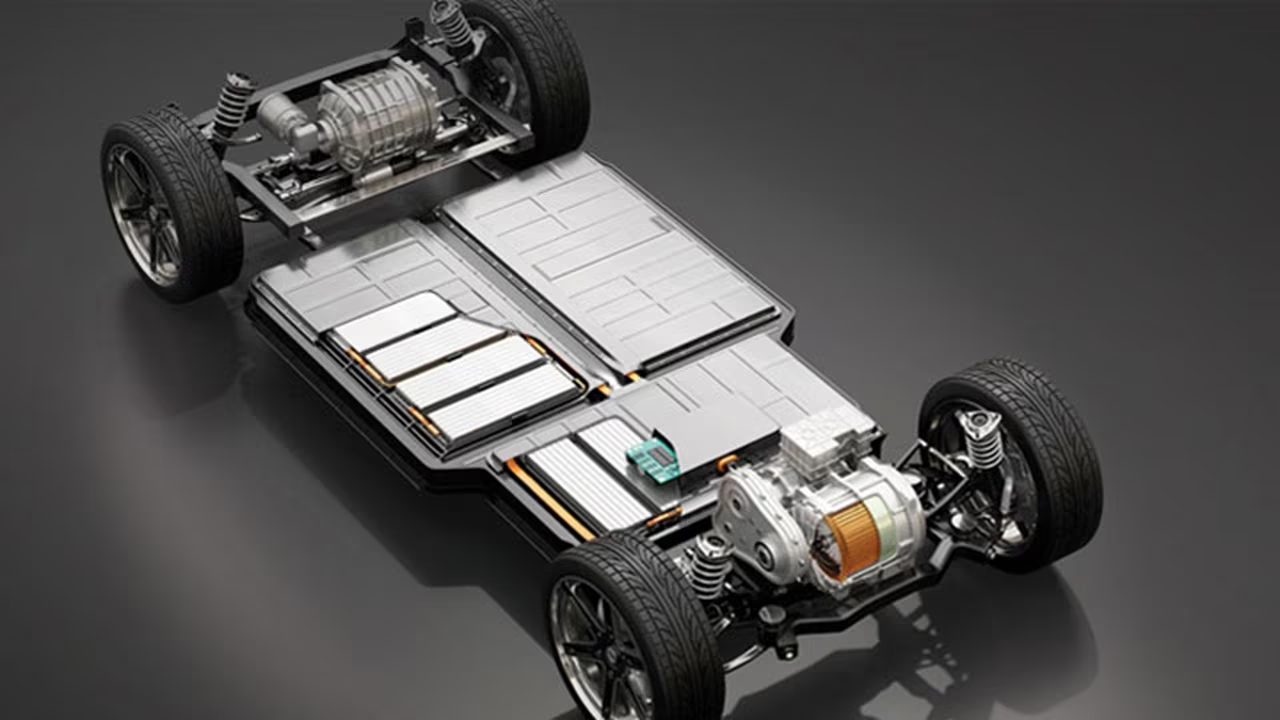

The current EV battery landscape

Volkswagen Mexico’s story of overcoming production challenges

When Volkswagen Mexico got caught up in the throes of production hitting a pause, they didn’t let it deter them. Instead, they decided to innovate and find new ways to transport their cars. This is the story of their partnership with Maersk and how they harnessed the power of cars in containers to meet their growing export demands.

What powers up automotive supply chains?

The impact of tariffs and geopolitics on supply chains

Making sense of complexity

Automotive supply chains have become even more complex. Today, the two drivetrains – internal combustion and electric – are sharing space on vehicle production lines. The epicentre of battery production has shifted to regional geographies, and technologies to reduce greenhouse gas (GHG) emissions are evolving at a pace that demands quick and seamless turnarounds.

With increasing customer demands and expectations, more parts are going into vehicles than ever before. As a component manufacturer, you now face an inherent need to produce more components than the OEMs themselves.

In the context of this industry-wide transformation, Antonio Fondevilla, Global Automotive Vertical Head of Maersk, explains the role that logistics can play in navigating this disruptive landscape.

Every component matters

Tens of thousands of components – big and small – go into the marvel that is an automobile. This means that all the parts need to be in the right place at the right time. Delays are not acceptable as they risk slowing down the assembly line.

To ensure that all your components move like clockwork, you need a logistics offering that gives you utmost control, reliability and transparency. From end to end, departure to destination, our automotive supply chain solutions are designed to give you just that.

Turning challenges into opportunities

Agility. It’s what your supply chain needs. Partnering with a lead logistics provider can give you a comprehensive look into the inner workings of an automotive supply chain. It allows you to develop better solutions led by digital innovation, integration, and a reliable team of highly talented professionals.

In view of the increasingly complex supplier relationships, it is important for the BMW Group to work together with suppliers to increase transparency and resource efficiency along the supply chain.

Panama regional distribution centre

One of the hallmarks of success is being at the right place at the right time. That’s exactly what our latest offering, the Panama regional distribution centre, makes possible. Strategically located at The Americas Hub, it offers last-mile distribution, air freight to 60+ countries, cross border and consolidation services, and a lot more. Experience world-class infrastructure and state-of-the-art logistics solutions, all from the Panama regional distribution centre.

You may also be interested in

Reach your full potential by letting us simplify and connect your supply chain from end to end.